Business Central for Manufacturing

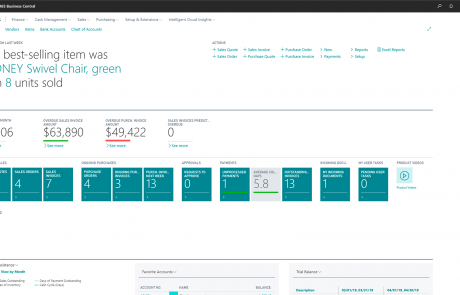

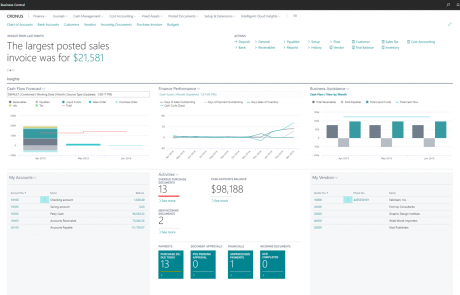

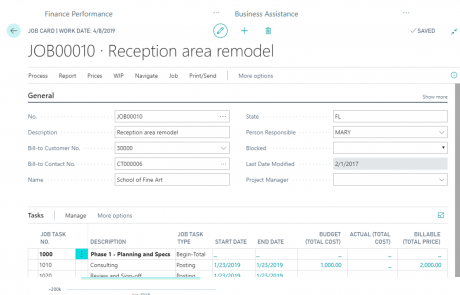

As your manufacturing business grows and production picks up, you need operational software to lighten the load. Microsoft Dynamics 365 Business Central does just that by managing supply planning, inventory, sales and delivery, and much more. Learn why growing and mid-sized manufacturers choose Business Central to manage operations.

How Business Central Solves Manufacturing Challenges

As an ERP solution, Business Central bridges the gap between manufacturing processes to track, simplify, and automate activities on the shop floor and beyond.

Who Is Business Central for Manufacturing Best Suited For?

Business Central for Manufacturing is designed for manufacturers that need better visibility, flexibility, and control across production, inventory, purchasing, and financials—without the rigidity of traditional manufacturing systems.

Backed by a Team of Business Central Experts

As an Business Central partner, Cargas helps growing manufacturers implement and scale Business Central ERP. We work closely with leadership and operations teams to ensure the platform supports visibility, control, and long-term growth across the business.

Explore our Business Central & Manufacturing Resources

Recent Articles

Check out our blog for helpful information about Business Central Software.

Business Central Demo Center

Check out our library of manufacturing software demos to see solutions like Business Central in action.

Manufacturing Articles

Check out our blog for helpful information about the role technology plays in manufacturing.

Let’s Chat

Still have questions? Get in touch with our expert team of software professionals.